Smart Compact Screw Compressor 4 - 18 kW, Efficient, Quiet

Fixed speed screw compressor Smart for a simple but efficient compressed air supply with the best compressed air quality. The V-belt driven screw compressors of the Smart series are easy to install, maintenance-friendly and space-saving.

Six versions of the SCC Smart compressor are available with a nominal motor power between 4 kW and 18 kW. Since the units require little space and are extremely quiet, they can be installed almost anywhere. All dimensions and power values can be found under the tab "Technical data".

With the SCC Smart, we offer an extremely low-priced compressor solution that is preset to 10 bar operating pressure as standard. On request, 8 and 12 bar are available at no extra charge.

Tip: Check your compressed air requirements and, if necessary, have the compressor configured for 8 bar right away to work even more energy-efficiently. (BAFA subsidy possible, see below!)

The advantages of the SCC Smart compressor in detail:

Belt drive

- efficient power transmission

- easy maintenance by replacing the belt

- Mechanical protection of motor and compressor

Large compressor stage

- slow speeds and thus longer service life

- lower temperatures and thus longer maintenance intervals

High motor efficiency

- helps to protect the environment through low energy consumption

- has a high efficiency due to its winding

- is protected against dust and splash water

Aftercooler and cooling air fan

- Air flow from bottom to top

- generously dimensioned components

- low temperatures

- High residual pressure at the compressor's exhaust air outlets

Easily complies with the Ecodesign Directive 2020

- far below EU energy consumption limits

- significantly lower electricity costs compared to conventional screw compressors

Long maintenance intervals of consumption points (4,000 operating hours)

- Reduced costs due to less frequent replacement of oil filter, air filter and oil separator element

Intake regulator

- With a generously dimensioned intake filter, the intake regulator ensures fully unloaded compressor start-up

Oil separator tank

- Large oil separator tank with integrated cyclone system for effective oil separation and low oil recirculation rates

Compressor stage and electric motor

- Large diameter rotor pairs result in low speeds and longer service life

- Motor efficiency class IE 3, protection class IP 54 and ISO class F

Low noise emissions, super-silenced

- You can install this compressor almost anywhere due to its low noise level.

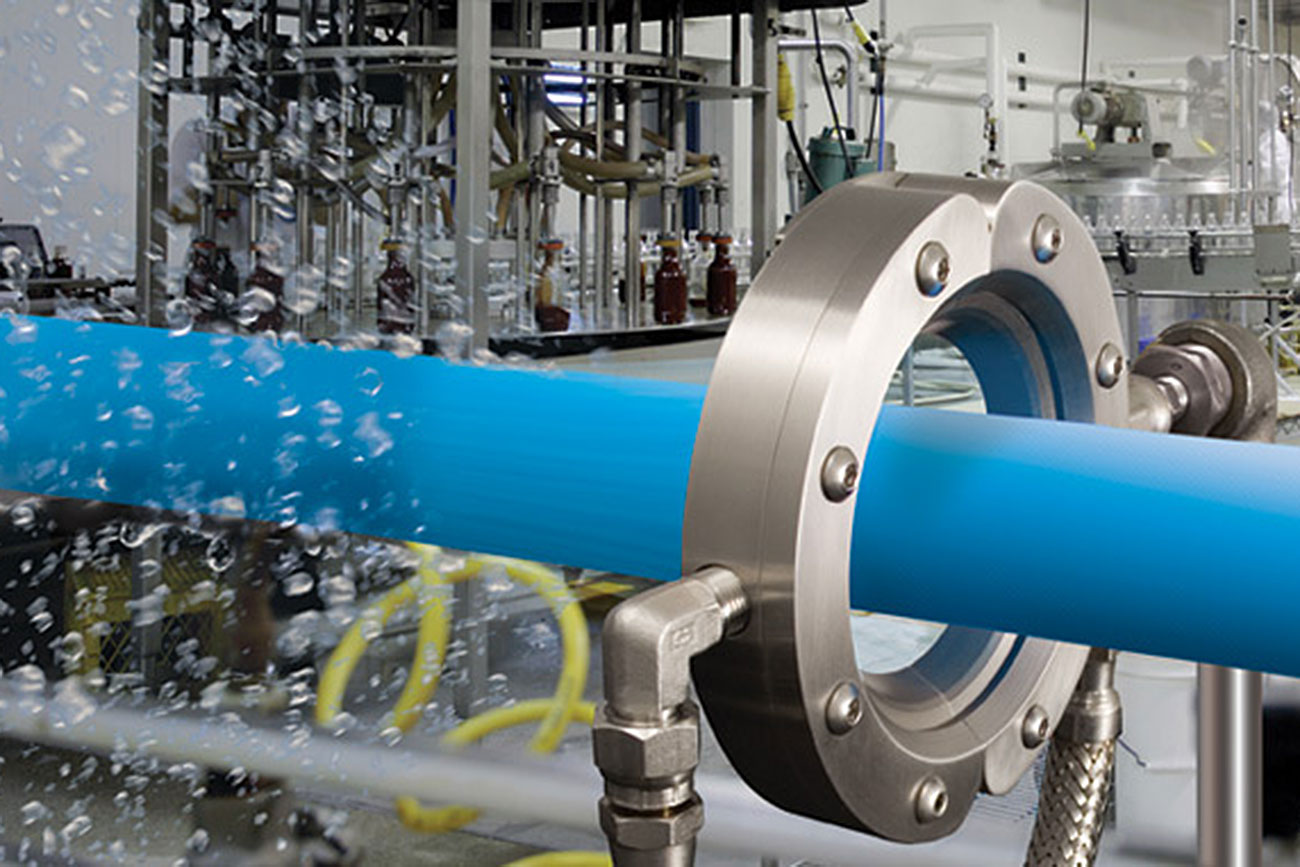

Internal piping

- enerously dimensioned

- results in low internal differential pressures and increases efficiency

"All-inclusive" version with receiver and dryer

- Our Smart compressors are also available as a practical plug & play all-inclusive package, recognisable by the suffix "TD" or "TD system".

- Such a Smart-TD system always includes a compressed air tank with a capacity of 270 or 500 litres and optionally various options for condensate treatment.

- Click here for the TD variants of the Smart family: Smart TD Compact Screw Compressor

For dimensions and performance values, see the "Technical data" tab.

High-quality accessories and spare parts from the manufacturer: We carry original SCC spare parts and accessories to supplement or repair your compressor.

Guarantee: The guarantee is 2 years or 5 years with the "worry-free" contract. For you, this means: calculable, realistic service costs and no nasty surprises in the event of an unplanned repair.

If certain requirements are met, parts of this compressor unit are eligible for BAFA funding.

Do all SCC screw compressors have a variable speed drive?

No - and that would not be customer friendly. Although variable speed compressors are considered to be the most energy efficient, this doesn't automatically make them the better choice. Instead, depending on the compressed air demand, a fixed speed compressor or a combination of non-controlled machines (for base load) and controlled models (for peak demand) may make sense.

In terms of SCC's current portfolio, the Smart and Storm series compressors are fixed speed. All other SCC compressors offer variable speed and are recommended for applications with fluctuating air requirements.

What type of motors drive SCC compressors?

SCC offers compressors with both IE3 asynchronous motors and IE4 permanent magnet motors. According to the efficiency classification of mains-powered three-phase motors (IE code), IE3 motors achieve the "Premium Efficiency" class. Prior to the introduction of IE4 motors, this was the highest energy efficiency class on the market. IE4 (Super Premium Efficiency) is fast becoming the new standard. These motors are even more efficient and are no longer as rare - and therefore expensive - as they were a few years ago.

Why are SCC compressors so quiet?

Compared to low-cost suppliers from Asia, quality manufacturers such as Germany's SCC pay attention to workmanship and small details. For example, to reduce noise levels, SCC compressors have effective insulation on the doors and a casing made from slightly thicker sheet metal.

What is there to know about the control of SCC air compressors?

The control of a compressor is to match the production of compressed air to the actual consumption of compressed air. At SCC, all compressors are fitted with the same advanced control system as standard. Operation is intuitive via a colour touch screen. The special feature is that up to 16 units can be connected and controlled in coordination with each other. This allows for particularly efficient energy consumption.

Software for real-time condition monitoring and machine data transfer to mobile devices is also available.

What does it mean to see the abbreviations P, G or AD 2000 on a compressed air tank?

The letters P and G are used to distinguish between painted (painted=p) and galvanised (galvanised=g) tanks. If there is no specific indication, the container is a painted standard container.

AD 2000 is the name of a set of technical regulations developed by the German "Arbeitsgemeinschaft Druckbehälter" under the auspices of the TÜV. The regulations for pressure vessel construction published in it are based on the safety and conformity criteria of the European Pressure Equipment Directive and take these further. It should be noted that the high requirements of the AD 2000 leaflets go beyond the minimum specifications of the international CE mark. With its containers in accordance with AD 2000, SCC thus offers products that meet a special safety requirement and underline the quality feature "Made in Germany". Companies that decide to purchase such a higher-quality tank benefit, among other things, from longer maintenance intervals and the resulting better plant availability.

What is the meaning of the TD code that can be selected as a variant on some SCC compressors?

The abbreviation TD stands for "Tank" and "Dryer". SCC's TD compressors are therefore 3-in-1 solutions consisting of a compressor, refrigerant dryer and matching compressed air tank. With these practical complete packages we can simplify and speed up the selection and ordering process for our customers. As plug and play solutions, the TD models also make it easier to commission the air system on site.

What air filters are supplied with the TD models?

All TD compressors automatically come with built-in pre and after filters. As the customer, you decide on the type of filter element. We are happy to advise you!

Why are some AQUARIUS sizes available with an integrated dryer and others without?

The difference in equipment is quite simply due to historical reasons. Aquarius models 31-46 were the first units in the range and were designed with a dryer as standard. It has to be taken into account that the space requirement increases when a dryer is integrated. Experience from discussions with customers has shown that many users prefer compact models. This is because smaller dimensions give them more freedom in choosing a location. Another factor is that companies often already have filter lines to which the Aquarius compressor can be connected. The following models have therefore been designed without a dryer.

Which SCC compressors meet the BAFA criteria and are therefore eligible for a grant?

At present, the SMART and FOCUS series of rotary screw compressors are eligible for an investment grant. However, as both the technical specifications of the compressors and the test criteria may change from time to time, we recommend that you contact our technical sales department. They will be able to advise you on which model not only meets the current BAFA requirements, but is also the best choice for your process.

Is there a heat recovery option for SCC compressors?

Yes, a complete heat recovery kit is available, specifically designed for use with SCC compressors. This option is particularly worthwhile for units of 22 kW and above. The ready-to-install heat recovery kit is integrated directly into the compressor to save space. Prices and further information available on request.